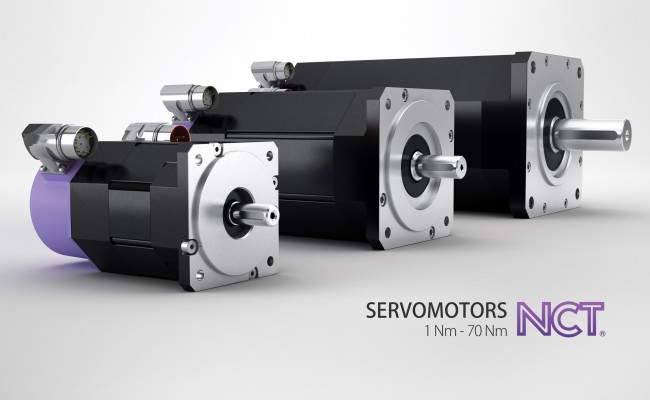

NCT Synchronous servomotors (axis motor)

NCT servomotor series, ,,A” and “Ai” motors are developed and produced by NCT Kft., are prepared especially for the precision drive of automatic machine-tools. Thanks to the special configuration, these motors meet high-level dynamic requirements of modern machine tools; they are built for long life, and have a maintenance-free operatio

Construction of the servomotors “A” series

The motors are permanent magnet synchronous machine with three-phase eight pole star-connected winding on the stator, and eight-pole rotor built from permanent magnets. The incremental or absolute value encoder is mounted on the non-drive end of the motor, which also provides information about the position of the pole-core relative to the stator winding. The stator is completely closed and the bearings of shaft extension are sealed. The cable connectors are also sealed. Thermal loss drained in a natural way -no external fan needed- so the motors are robust. Both the excitation around the boundary of the stator and the induction of the air-gap produced by the rotor are quite sinusoidal, so the torque of the motor can be exactly controlled independently of the pole-core position, because of this an extremely accurate speed control can be realized appropriately. The color of data plate of “A” series servomotors is yellow. http://www.nct.hu/pdf/Pros/nct200ken.pdf

Construction of the servomotors “Ai” series

The construction of series “Ai” motors is identical to the series “A” motors except the material of the rotor magnets. Thanks to the rare earth metal magnets (Neodymium or Samarium-cobalt) on the rotor of the “Ai” motors they can produce much more torque, speed and power than “A” in the same motor size, and inertia of “Ai” motors much less than adequate “A” motors. The color of data plate of “A” series servomotors is white. http://www.nct.hu/pdf/Pros/nct200ken.pdf

NCT Asynchronous servomotors (Spindle motors)

NCT asynchronous servomotors have been specifically designed for spindles of automatic machine tools. Thanks to the special configuration, these motors meet high-level dynamic requirements of modern machine tools; they are built for long life, and have a maintenance-free operation. The hollow shaft of AiS spindle motors allows cooling-lubricating medium to be fed to an internally cooled tool (CTS) in case of direct drive.

AMS type motors can call as compact power spindle, because these integrated to a lathe spindle. Their dynamic rigidity and low vibration tendency make a further leap in machining quality http://www.nct.hu/pdf/Pros/nct200ken.pdf